| New-tecH 9820/02

ELEKTRONiK GflZLt) iUK DiKl§ MAKiNESi Uygulama: Bay — Bayan dig giyim STANDART OZELLiKLER •2500 devir/dakika ile yuksek verimlilik •Kullammi kolay galigma paneli •Hassas kumaglarda mCikemmel dikig kalitesi (Itjne batig noktasi hassasiyeti arttirildi. •Dikig atlama sayisi azaltildi] • Qaligma kolayh^i saQIayan genig ig yerlegtirme alam [120 mm derinlik] •Kolay bakim [merkezi yaCjlama sistemi, toplanabilir iplik artiklari, temizlenebilir ilik kumag pargasiklari] ■ Qevreye saygili •Bakim personeli igin kolay ayar yapma imkam •Duguk gug tuketimli ekonomik model •Kullammi kolay LCD galigma paneli (simgelerve harflerin kullamldigi kolay ekran, kisayol tuglari, gok dilli ekran, hassas ayarlama yapilabilen LCD panel] |

| New-tecH 9820/02

ELECTRONIC EYELET BUTTON HOLER MACHINE Application: Men/Women Ready Made Garments STANDARD FEATURES • Sewing speed up-to 2,500 rpm improves productivity • Fine finishing of button holes. (With the highly rigid feed mechanism with servo control,stitch point is very precise.Skip stitches are reduced] ■ Large arm pocket allowing smooth material handling (120 mm depth] • Sewing with less noise ■ Easy Maintenance (Centerilazed Lubrication system, Thread waste can be collected, eyelet cloth chips can be collected] • Environment conscious ■ Easy adjustment favorable to maintenance staff ■ Economical model with low power consumption ■ Liquid Crystal Display (LCD] With icons and letters, easy to understand, shortcut keys. Multilingual display.Fine adjsutment can easily be made. |

| New-tecH 9820/02 |

| New-tecH 9820/02 |

| MAQUINA DE OJAL DE BOTELLA ELECTRONICA

Aplicacion: Prendas terminadas Hombre/Mujer CARACTERISTICAS PRINCIPALES ■Velocidad de costura hasta 2,500 rpm (mejora la productividad] •Acabado fino de los ojales. (con el mecanismo de alimentacion altamente rigido con servo control, punto puntada es muy precisa. Las puntadas saltadas se reducen. ■Brazo largo que permite la manipulation de materiales suaves о delicados (120 mms. De profundidad]. •Costura con reduction de ruid. •Facil mantenimiento (sistema de lubrication centralizado], ■Los residuos de hilo у tela pueden ser recogidos. •Ambiente consciente. •Facil ajuste que favorece el mantenimiento del propio personal. •Modelo economico con bajo consumo de energia electrica. •Display de Crista! Liquido (LCD] con iconos у letras, facil de entender. • Teclas de acceso directo. Display multilenguaje. Ajustes finos pueden realizarse de manera muy sencilla. |

| ЭЛЕКТРОННЫЙ ПОЛУАВТОМАТ ДЛЯ ПЕТЕЛЬ С ГЛАЗКОМ

ПРИМЕНЕНИЕ: МУЖСКАЯ И ЖЕНСКАЯ ВЕРХНЯЯ ОДЕЖДА СТАНДАРТНАЯ КОМПЛЕКТАЦИЯ • Скорость до 2500 стежков в минуту ■Отличное выполнение петель (Благодаря высокоточной системе подачи с сервоприводом. ■ Уменьшена вероятность пропуска стежков) • Большой вылет рукава обеспечивает легкое размещение ткани (глубина до 120 мм) ■ Понижен уровень шума ■ Легкое обслуживание (Централизованная система смазки, сбор обрезков нити, сбор высеченных глазков) ■ Энергосбережение ■ Легкость в настройке ■ ЖК дисплей с буквами и значками легкий в понимании. Быстрые клавиши. • Многоязычный дисплей. Легкость в выполнении точных настроек. |

| TEKNiK OZELliKLER SPECIFICATIONS | -00 | -01 | •02 | ||

| iPLiK

KESiCl THREAD TRIMMER |

OST iPLiK KESiCi UPPER THREAD TRIMMER | Uzun iplik kesimi Long thread cot | Uzun iplik kesimi Long thread cut | Kisa iplik kesimi Short thread cut | |

| ALT iPLiK KESiCi LOWER THREAD TRIMMER | Yok

None |

Uzun iplik kesimi Long thread cut | Kisa iplik kesimi Short thread cut | ||

| ANA UYGULAMALAR MAIN APPLICATIONS | Kadin giyimi Ladies’ wear | Erkek giyimi, gunluk giyim Men’s wear, casual wear | Kotlar I Kotlar, pantolonlar Jeans 1 Jeans, trousers | ||

| DifiER UYGULAMALAR OTHER APPLICATIONS | Erkek giyimi, gunluk

giyim,kotlar,pantolonlar Men’s wear, casual wear .jeans, trousers |

Kadin giyimi,kotlar.pantolonlar Ladies’ wear, jeans, trousers | |||

| CZELllKLER

FEATURES |

Sadece Cist iplik iplik kesici ile kesilir. SO mm uzunlufuna kadar itikler dikilebilir. Only the upper thread is cut by the thread trimmer.euttonholes up to 50 mm long can be sewn. | Tiim iplikler iplik kesiciler ile uzun olarak kesilir. Uzun iplik u?lari sonraki ijlemlerde sikica tutulabilir.Hassas kisa u$ veya elle kesim gerektiren durumlar i?in uygundur.

All the threads are cut long by the thread trimmers. The long thread ends can be securely held in the subsequent process.lt is suitable for cases that require accurate short end or manual trimming |

Tiim iplikler iplik kesiciler ile kisa olarak kesilir. 8u ijlem elle kesim derdinden kurtarir ve iplik tuketimini azaltir.

All the threads are cut short by the thread trimmers. This saves the trouble of manual trimming and reduces consumption of thread. |

||

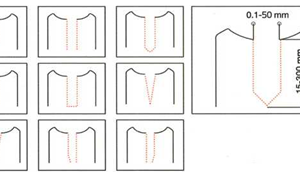

| DiKi$$EKLi SEWING SHAPE | fill» | jfl Уш | fill! | III | |

| DlKi$ uzunluGu SEWING LENGTH | Gozlu ilik: 8-SO mm Duz ilik: S-SO mm Eyelet buttonhole: 8-50 mm Straight buttonhole: 5-50 mm | Gozlu ilik: 8-42 mm Duz ilik: 5-42 mm Eyelet buttonhole: 8-42 mm Straight buttonhole: 5-42 mm | 22-30 mm L1422 (14-22mm) L1826 (18-26mm) L2634 (26-34mm) L3442 (34-42mm) | 18-26 mm L1422 (14-22mm) L2230 (22-30mm) L2634 (26-34mm) L3442 (34-42mm) | |

| К LAMER UZUNLUfiU (STANDART) LENGTH OF WORK CLAMP (STANDARD) | 30 mm | 30 mm | 26 mm | ||

| BALTA UZUNLUGU (STANDART) LENGTH OF HAMMER (STANDARD) | 22 mm | 24 mm | 20 mm | ||

| BALTA UZUNLUSU (ACCESSORY) LENGTH OF HAMMER (ACCESSORY) | 30 mm | 28 mm | 24 mm | ||

| DiKiSHIZI/SEWING SPEED | 1,000 — 2,500 dv/dk (sti/min) | ||||

| DiKij SIKLlGl / STITCH PITCH | 0.5-2.0 mm | ||||

| ZiGZAG GENijllSi / ZIGZAG WIDTH | 1.5- 5,0 mm(Mekanik olarak 4,00 mm’ye kadar, zigzag geni$lik telafisi ile 5,00 mm’ye kadar.)

1.5- 5,0 mm(Up to 4,00 mm in mechanical, up to 5,00 mm with zigzag width compensation) |

||||

| ZiGZAG GENiSLiSI (FABRlKA AYARI)/ ZIGZAG WIDTH (FACTORY SETTING) | 2.5 mm | 3.00 mm | ||||

| KUYRUK PUNTERiZ UZUNLUGU TAPER BARTACK LENGTH | 0-20 mm | ||||

| KLAMERYOKSEKLiSi CLAMP HEIGHT | Standart olarak 12 mm (16 mm’ye kadar mumkiindur) 1 16 mm 12 mm as Standard (Available up to 16 mm) | | ||||

| BA$LAMA METODU STARTING METHOD | Pedal (Тек pedalli tip, iki pedallt tip), El diigmesi (iki levyeli tip)

Foot switch (Treadle type. Two-pedal type), Hand switch (Two-lever type) |

||||

| BESLEME MEKANiZMASI FEEDMECHANSIM | 0; puls motoru (X,Y,6) ile aralikli besleme intermittent feed by 3 pulse motors (X,Y,8) | ||||

| IGNE/NEEDLE | 00X558 Nm80 — Nml20 (SCHMETZ) | ||||

| iGNE(FABRiKA AYARI) NEEDLE (FACTORY SETTING) | 00×558 NmlOO | 00×558 Nm90 | 00×558 NmllO | ||||

| iS PANEli igiN DESTEKLENEN DiUER LANGUAGES SUPPORTED FOR OPERATIONAL PANEL | Japonca, ingilizce, Cince, Almanca, Fransizca, ispanyolca, italyanca, Portekizce, Tiirk?e ve Endonezya, Vietnam ve Rus?a Japanese, English, Chinese, German, French, Spanish, Italian, Porteguese, Turkish, Indonesian, Vietnamese and Russian | ||||

| GUVENliK EKiPMANI SAFETY EQUIPMENT | Acil durdurma fonksiyonu ve ariza durumunda emniyet devresi taraftndan devreye sokulan dahili durdurma tertibati Emergency stop function and built-in automatic stopping device activated by safety circuit in case of trouble | ||||

| OST MiL MOTORU UPPER SHAFT MOTOR | AC servo motor 5S0 W | ||||

| HAVA BASINCI / AIR PRESSURE | Ana regulator: 0.5 Mpa, Balta basin? regiilatoru: 0,4 Mpa Main Regulator: 0.5 Mpa, Hammer Presser Regulator: 0,4 Mpa | ||||

| HAVA SARFiYATI/AIR CONSUMPTION | 43,2 l/dk.(min) (8 ?evrim (cycles) /dk. (min)) | ||||

| AGlRLIK

WEIGHT |

Makine kafasi: Yaklajik 120 kg., i? paneli: Yakla}ik 0,6 kg., Kumanda kutusu: 14,2 -16,2 kg (Ulkeye gore farklilik gosterir) Machine head: Approx. 120 kg.. Operational panel: Approx 0,6 kg.. Control box: 14,2 -16,2 kg (depending on the destination) | ||||

| GO? KAYNAGl — GUC TOKETiMi POWER SUPPLY-POWER CONSUMPTION | Тек fazli 100V/200V, U? fazli 200V/220V/380V/400V, 400VA Single Phase 100V/200V, 3-phase 200V/220V/380V/400V, 400VA | ||||

There are no reviews yet.